Is it truly possible to work with electricity safely, even when dealing with live wires? The answer, unequivocally, is yes, but it demands a rigorous adherence to safety protocols, a deep understanding of the tools at your disposal, and an unwavering respect for the potential dangers involved.

Electrical work, by its very nature, presents a formidable array of hazards. The potential for electric shock, burns, and even fatalities is ever-present, making a thorough comprehension of safety procedures absolutely paramount. This guide provides a comprehensive overview of the crucial practices needed to safely test live wires.

| Topic | Details |

|---|---|

| Importance of Testing | Testing live wires is a critical safety measure to prevent electric shocks, identify faulty circuits, ensure safe installation, and comply with safety regulations. Electrical hazards account for a significant number of workplace injuries and fatalities, according to the National Institute for Occupational Safety and Health (NIOSH). |

| Essential Tools |

|

| Safety Steps |

|

| Common Mistakes to Avoid |

|

| Advanced Techniques |

|

| Electrical Safety Regulations | In the United States, OSHA provides guidelines, including lockout/tagout procedures, PPE requirements, and regular equipment inspections. Compliance protects workers and ensures legal adherence. |

| Troubleshooting Common Issues |

|

| Best Practices |

|

| Additional information | This guide is designed for both beginners and professionals who want to enhance their skills in electrical testing. |

When dealing with electricity, the potential for mishaps is ever-present. That is why a comprehensive understanding of the tools and techniques used to test live wires safely is so important. This guide is not just for seasoned electricians; it's equally vital for DIY enthusiasts embarking on electrical projects. By understanding the fundamental principles, you can navigate these potentially hazardous situations with heightened confidence and, most importantly, with a firm commitment to safety. As the National Institute for Occupational Safety and Health (NIOSH) has reported, electrical hazards are a significant source of injuries and fatalities in the workplace.

- Bruce Boltz Insights Lessons From A Business Trailblazer

- Caitlin Clark Did She Sign A European Basketball Contract

The equipment you employ is as crucial as the knowledge you possess. A detailed understanding of each tool's function is a prerequisite for any work. Below is a deeper dive into the critical instruments necessary for live wire testing.

1. The Multimeter

The multimeter stands as an indispensable tool for anyone involved in electrical work. It's the workhorse of the electrical trade, capable of measuring voltage, current, and resistance. Its versatility makes it an essential component of any electrician's toolkit. When choosing a multimeter, pay close attention to its impedance rating; a high-impedance multimeter is crucial to prevent drawing current from the circuit being tested, which could lead to inaccurate readings or even damage the device.

2. The Voltage Tester

A voltage tester, often a simple device, provides a quick and easy way to determine whether a wire is live. It typically features two probes that, when placed on a wire, will illuminate if voltage is detected. Non-contact voltage testers offer an added layer of convenience and safety, as they can detect the presence of voltage without requiring direct contact with the wire. This feature is particularly valuable when working in environments where physical contact might be difficult or potentially risky.

3. Insulated Gloves

Safety should always be paramount. Insulated gloves are an absolute necessity when working with live wires. These gloves are specifically designed to prevent electric shocks by providing a protective barrier between your hands and the energized conductors. They are a crucial piece of personal protective equipment (PPE) and should always be worn when any potential for contact with live wires exists. Remember, the electricity can be unpredictable, so protect yourself!

4. Protective Eyewear

Protective eyewear is more than just a suggestion; it's a critical piece of PPE. The potential for sparks or debris to be generated during electrical testing is real, and protecting your eyes from injury is paramount. Safety glasses or, preferably, a face shield will offer the necessary protection to keep your vision safe during any electrical testing procedures.

The ability to accurately and safely test live wires is built on a foundation of systematically following established procedures. Here are the steps to undertake live wire testing.

Step-by-Step Guide to Safe Live Wire Testing

Step 1: De-energizing the Circuit - Turning off the Power: Before you even think about testing, the first and most critical step is to ensure that the power is off. Locate the circuit breaker or fuse that controls the circuit you're working on and turn it off. This step minimizes the risk of electric shock and any potential damage to equipment. It's a simple act, but it is the cornerstone of your safety protocol.

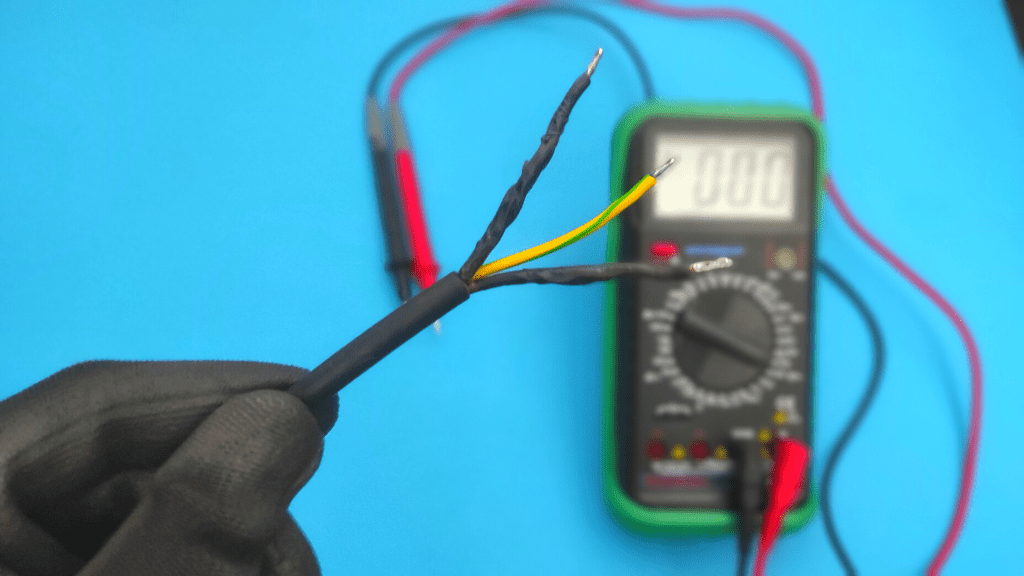

Step 2: Verification - The Double-Check: Never assume the power is off, even after flipping the breaker. Utilize a non-contact voltage tester to confirm that the wire is not energized. This double-check ensures that the circuit is truly de-energized, providing an additional layer of protection and preventing potentially dangerous situations. It's always better to be safe than sorry; take the time for this step.

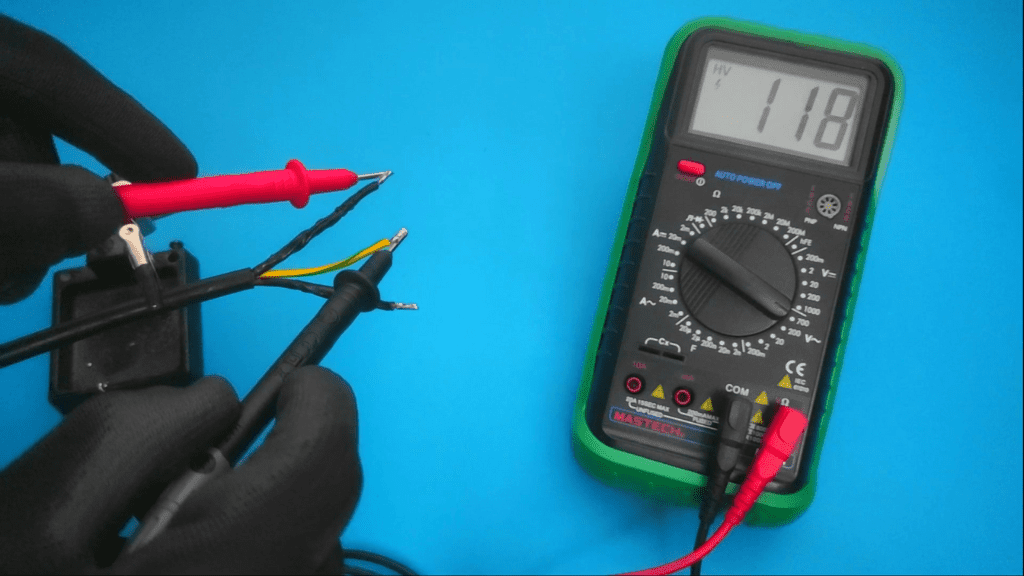

Step 3: Multimeter Configuration: Set your multimeter to the appropriate voltage setting. For household circuits, thats typically 110V or 220V, depending on your region and the standard. Always start with a higher voltage setting to avoid damaging the meter. This ensures that the meter is prepared to accurately measure any potential voltage present in the circuit, ensuring accuracy of the testing process.

Step 4: The Test: Finally, with your safety precautions in place, you can now test the wire. Carefully place the probes of the multimeter onto the wire you want to test. The multimeter will display the voltage reading if the wire is live. If the multimeter registers no reading, then, the wire is not live, and you can proceed with your work. If you get a reading, STOP and re-evaluate your process. Ensure you have followed all the safety steps.

Even experienced professionals are susceptible to making mistakes. Awareness of these common pitfalls will allow you to avoid them and work more safely.

Common Mistakes to Steer Clear Of

Ignoring PPE: Never work on live wires without the appropriate personal protective equipment. This includes insulated gloves, protective eyewear, and appropriate clothing. PPE is the shield that protects you.

Using Damaged Tools: Inspect your tools before each use. Damaged or faulty tools can give inaccurate readings or even create additional hazards. A tool is only as good as its condition; keep your equipment in proper working order.

Skipping the Double-Check: Always verify that the power is off before beginning any work. The double-check is a simple but critical safeguard.

Working Without Power Off: This is the most dangerous mistake. Always turn off the power at the source before working on any electrical circuit. Dont put yourself at risk. Never work on a live circuit.

For complex electrical systems, these advanced techniques are essential to a comprehensive approach to electrical safety.

Advanced Techniques

Phase Identification: When dealing with three-phase electrical systems, accurate phase identification is critical. Utilizing a phase sequence indicator helps you ensure the correct phase order, which is crucial for the proper functioning of the system. This prevents operational errors and ensures optimal performance.

Ground Fault Detection: Ground faults can occur when an unintended electrical current flows through unintended paths. Ground Fault Circuit Interrupters (GFCIs) can detect and prevent these faults, protecting both equipment and personnel.

Harmonic Analysis: This technique is particularly useful in industrial environments. It helps detect distortions in electrical signals, ensuring the stability and efficiency of your electrical systems. By understanding and addressing harmonics, you can maintain the integrity and longevity of your equipment.

It is a complex landscape and electrical safety regulations can vary from country to country, but the core message remains the same: Testing live wires safely is of utmost importance. The Occupational Safety and Health Administration (OSHA) in the United States provides critical guidelines that set the standard for safety.

OSHA and Electrical Safety

The Occupational Safety and Health Administration (OSHA) in the United States provides a comprehensive set of guidelines for electrical safety, outlining essential protocols and procedures. These guidelines serve as a foundational resource for safeguarding workers from electrical hazards. They encompass several key areas, including:

Lockout/Tagout Procedures: OSHA mandates the use of Lockout/Tagout (LOTO) procedures, which are critical for controlling hazardous energy. LOTO involves de-energizing equipment and securely locking and tagging energy-isolating devices. This prevents accidental energization during maintenance or repair, providing an additional layer of safety for workers.

Personal Protective Equipment (PPE) Requirements: OSHA specifies the required PPE for electrical work, including insulated gloves, protective eyewear, and flame-resistant clothing. These are essential for preventing electric shock, burns, and other injuries that may result from electrical incidents. These are the building blocks of electrical safety.

Regular Equipment Inspections: OSHA mandates regular inspections of electrical equipment. These inspections are vital to identify and address any defects, damage, or deterioration that could compromise safety. Proper and regular inspections minimize the potential risks of accidents.

Adherence to OSHA guidelines not only protects workers, but also ensures legal compliance, minimizing the risk of fines and legal liabilities.

Even with careful testing, there are certain common issues that you may encounter. Here's how to effectively address these problems.

Troubleshooting Common Issues

Inaccurate Readings: A faulty multimeter or incorrect settings can cause this. To resolve the issue, calibrate the multimeter and verify the settings.

No Voltage Detected: Possible issues include power supply problems or broken wires. Begin by inspecting the power source and checking the wiring connections.

Intermittent Voltage: Loose connections or faulty switches can create intermittent voltage. To resolve, tighten all connections and replace any faulty components.

Implementing best practices is an important step in maximizing safety and efficiency when testing live wires. Here are some essential tips to keep in mind.

Best Practices

Wear PPE: This is the single most crucial step. Always wear the proper personal protective equipment, including insulated gloves, safety glasses, and appropriate clothing.

Insulated Tools: Use tools with insulated handles. This helps minimize the risk of accidental contact and electric shock.

Work Area: Keep your work area clean and organized to reduce the risk of tripping hazards and accidental contact with live wires.

Follow Instructions: Adhere to the manufacturer's instructions for all equipment. Following these instructions will help you use the equipment correctly and reduce the risk of accidents.

- Honey Pine Makeup Your Guide To Natural Beauty Skincare

- Shadman Keemstar From Youtube Pioneer To Industry Icon