Why does the selection of a valve typespecifically, a gate valve versus a ball valvematter so profoundly in the intricate world of industrial fluid control? The answer lies in the very essence of their purpose: ensuring the safe, efficient, and reliable operation of complex systems.

Valves, often unsung heroes of the industrial landscape, are the crucial components that orchestrate the flow of fluids across a myriad of applications. From the depths of oil and gas pipelines to the delicate processes of water treatment and chemical manufacturing, these devices meticulously regulate pressure, control direction, and, ultimately, ensure operational integrity. The choice between a gate valve and a ball valve is not merely a matter of preference; it is a critical decision predicated on the specifics of the task at hand, demanding a nuanced understanding of their unique capabilities and limitations. The selection process is a critical one and demands close attention to detail, the type of fluid in question, the pressure demands that must be met, and the frequency of operation that the system requires, these factors are weighed. The selection of a valve type often serves as the linchpin in the design and operational success of systems spanning vast industries.

| Gate Valve vs. Ball Valve: Quick Reference | ||

|---|---|---|

| Key Feature | Gate Valve | Ball Valve |

| Operation | Linear Motion | Quarter-Turn (90-degree rotation) |

| Sealing | Excellent for On/Off | Excellent for Frequent Operation |

| Applications | Water supply, oil pipelines, steam | Chemical processing, gas pipelines, hydraulic systems |

| Advantages | Full bore, high-pressure/temp | Quick operation, excellent sealing, compact |

| Disadvantages | Not for throttling, slower operation | Higher cost, seat wear, not for large diameters |

| Cost | Generally More Economical | Generally More Expensive |

Let's begin by unpacking the foundational elements, providing clarity of the distinct roles each plays and how they contribute to the broader functionality of industrial systems.

- Snoop Doggs Crip Walk History Moves Amp Cultural Impact

- Carnival Dress Guide How To Shine Celebrate In Style

Introduction to Gate Valve and Ball Valve

In the realm of fluid control, two primary contenders emerge: the gate valve and the ball valve. Each employs a distinct mechanism to regulate flow, designed to meet the varying demands of industrial applications. The appropriate selection relies upon a deep appreciation of the operational parameters. This includes a comprehensive understanding of the process fluid characteristics, the pressures under which the system must operate, and the frequency of valve actuation required. These critical decisions help determine which valve type will meet the demands of a given application.

What is a Gate Valve?

A gate valve, often referred to as a sluice valve, is a linear motion valve that harnesses a gate or wedge to control the flow of fluid. Its primary function revolves around an on/off service model, making it unsuitable for applications that require throttling. These valves are particularly advantageous when a full bore opening is essential, such as in water supply networks, oil pipelines, and steam systems. Gate valves come in two primary configurations: the parallel and wedge designs. The parallel configuration features a flat gate, while the wedge design incorporates a slightly tapered gate to ensure a tight seal. Both designs are effectively engineered to prevent fluid leakage when in a fully closed state, ensuring operational integrity.

Key Features:

- Diy Lightning Mcqueen Costume Stepbystep Guide

- Dti Jewelry Overload Your Ultimate Guide To Smart Buys

- Full bore opening for unrestricted flow

- Designed for on/off service

- Not suitable for throttling

What is a Ball Valve?

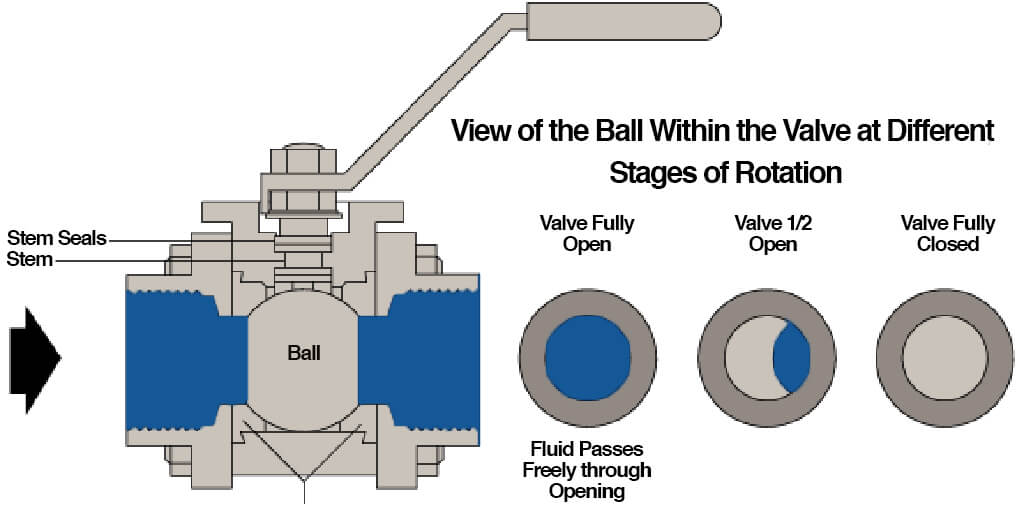

Contrasting the gate valve, the ball valve employs a spherical disc with a bore to modulate flow. It operates with a quarter-turn mechanism, enabling it to be fully opened or closed with a 90-degree rotation. Ball valves are highly regarded for their exceptional sealing characteristics, making them a staple in operations that necessitate frequent actuation. They are commonly deployed in applications like chemical processing and gas pipelines. Ball valves encompass a range of designs, including full-bore, reduced-bore, and trunnion-mounted variants. Each design presents unique advantages, tailored to meet specific application demands.

Key Features:

- Quarter-turn operation for quick shut-off

- Excellent sealing capabilities

- Suitable for frequent operation

Design Differences Between Gate Valve and Ball Valve

The physical design of a valve exerts a profound influence on its performance and suitability for a given application. A deeper dive into the design distinctions between gate valves and ball valves is essential for making informed decisions:

- Gate Valve Design: Gate valves incorporate a body, bonnet, stem, and a gate. The gate moves perpendicularly to the flow path, either allowing or impeding fluid transit. Gate valves are typically larger and heavier than their ball valve counterparts, which can be a significant factor in applications where space is at a premium.

- Ball Valve Design: Ball valves feature a spherical disc equipped with a bore that aligns with the flow path when open. The ball rotates within the valve body, delivering a robust seal when closed. Ball valves generally boast a more compact and lightweight profile, positioning them ideally for scenarios where space is constrained.

Applications of Gate Valve and Ball Valve

Understanding the applications of gate and ball valves is critical in making the right choice for a given operation. Their designs lend themselves to specific functions and environments:

Applications of Gate Valves

Gate valves excel in scenarios where a full bore opening is mandated, and frequent operation isn't required. They are often found in the following applications:

- Water supply systems

- Oil and gas pipelines

- Steam systems

- Fire protection systems

Applications of Ball Valves

Ball valves are the go-to choice for operations demanding rapid shut-off and frequent actuation. Their versatility makes them suitable for a wide range of applications:

- Chemical processing

- Gas pipelines

- Hydraulic systems

- Food and beverage industry

Advantages of Gate Valve and Ball Valve

Both gate and ball valves come with their own set of benefits, making them ideal for a range of uses:

Advantages of Gate Valves

Gate valves are favoured for several reasons, making them highly desirable in their respective fields:

- Full bore opening for unrestricted flow

- Reliable sealing performance

- Suitable for high-pressure and high-temperature applications

Advantages of Ball Valves

Ball valves also have several distinct advantages, making them a common choice in a variety of applications:

- Quick and easy operation

- Excellent sealing capabilities

- Compact and lightweight design

Disadvantages of Gate Valve and Ball Valve

No valve type is perfect; both gate and ball valves come with their own set of limitations:

Disadvantages of Gate Valves

Gate valves, despite their advantages, have limitations that must be considered:

- Not suitable for throttling applications

- Slower operation compared to ball valves

- Prone to wear and tear over time

Disadvantages of Ball Valves

Ball valves, too, have drawbacks that should be considered when making a selection:

- Higher cost compared to gate valves

- May experience seat wear in abrasive fluid applications

- Not ideal for large-diameter applications

Maintenance Requirements for Gate Valve and Ball Valve

Regular maintenance is key to ensuring optimal performance, and the following maintenance tips apply to both gate and ball valves:

Gate Valve Maintenance

- Inspect the stem and packing for signs of wear

- Check for leaks around the bonnet and body

- Lubricate moving parts to prevent seizing

Ball Valve Maintenance

- Inspect the ball and seat for wear and tear

- Check for leaks around the body and stem

- Ensure proper lubrication of the stem and ball

Cost Considerations for Gate Valve and Ball Valve

When choosing between gate and ball valves, cost becomes a major factor. Gate valves are often more cost-effective, particularly in applications requiring large diameters. However, the enhanced sealing and performance characteristics of ball valves may warrant the higher cost in certain situations.

Comparison of Gate Valve and Ball Valve

A direct comparison of the two types can aid in the decision-making process:

- Operation: Gate valves are linear motion valves; ball valves are quarter-turn valves.

- Sealing: Gate valves seal well in on/off services, whereas ball valves excel in frequent-operation scenarios.

- Size: Gate valves tend to be larger and heavier; ball valves are more compact and lightweight.

- Cost: Gate valves are generally more cost-effective, especially in applications using large diameters.

How to Select Between Gate Valve and Ball Valve

Selecting the right valve involves weighing several factors:

- Application Requirements: Analyze the fluid type, pressure, and temperature demands.

- Operation Frequency: Ball valves are best for frequent use, gate valves for infrequent use.

- Space Constraints: Ball valves are optimal where space is limited.

- Cost Considerations: Balance performance with budget needs.

Future Trends in Valve Technology

The future of valve technology is bright, with advancements in design and materials expected to improve performance and reliability. Innovations, such as smart valves with integrated sensors and digital controls, are gaining popularity. These offer better monitoring and maintenance capabilities. Staying informed of these trends ensures the selection of the best valve for future applications.

- Prank Calls Funny Ideas Etiquette Hilarious Examples

- Marry Me Pasta A Delicious Dive Into The Global Pasta Sensation